Types of Cable Trays: A Complete Guide for Industrial Applications

In contemporary industries, effective cable management is not merely wire organization, it is about ensuring safety, longer life, and easy maintenance. That is where cable trays fit in. Cable trays are systems that are meant to support, guard, and route electrical cables in industrial settings like manufacturing plants, power stations, data centers, and business buildings. Depending on the application, load conditions, and ambient conditions, various types/styles of cable trays are available, so appropriate selection relies on them.

Different Types of Cable Trays for Industrial Applications

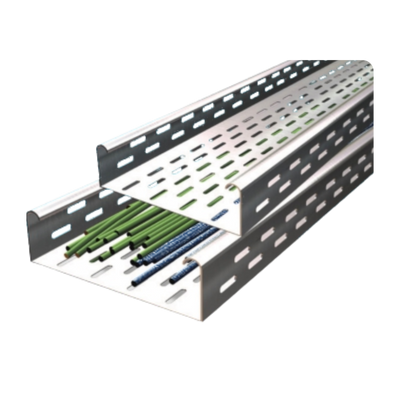

1. Perforated Cable Tray

When cables need more support than what ladder trays offer, industries turn to the Perforated Cable Tray. With closely spaced rungs or a bottom plate featuring small openings, this tray provides extra protection and partial ventilation.

The trough design is ideal for moderate heat-generating cables, ensuring both support and airflow. Applications include commercial buildings, telecom industries, and IT setups where medium-sized cables are in use

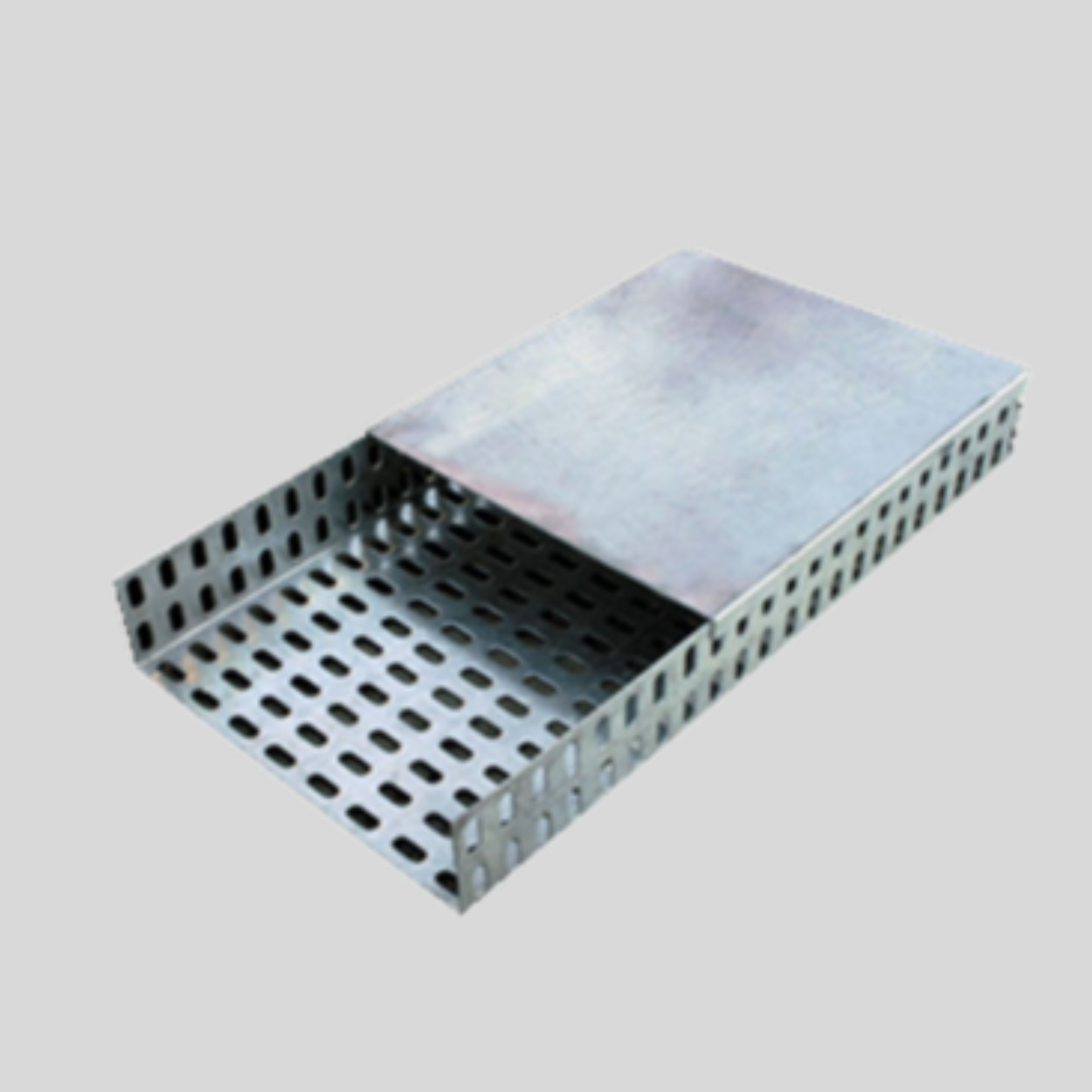

2. Raceway (along with cover always)

As the name suggests, Raceway (solid base trays) come with a completely covered bottom. This makes them the go-to choice when cables require maximum protection against dust, debris, and falling objects.

Solid trays are common in food processing plants, paper mills, or cleanroom facilities where contamination is a serious concern. Since there is no ventilation, they are best suited for low-heat or sensitive cables. Industries that demand clean and shielded cabling benefit significantly from this design.

3. Ladder Cable Trays

A Ladder Cable Tray is a widely used cable management system designed to support and route large volumes of power and communication cables. Its ladder-like structure allows for excellent ventilation, preventing overheating and ensuring longer cable life. The open design also makes it easy to install, inspect, and maintain cables without disrupting existing setups. Known for its durability and strength, ladder cable trays are ideal for industrial and commercial environments where heavy-duty cable support is required. They are commonly used in power plants, factories, and data centers to provide reliable, organized, and secure cable pathways.

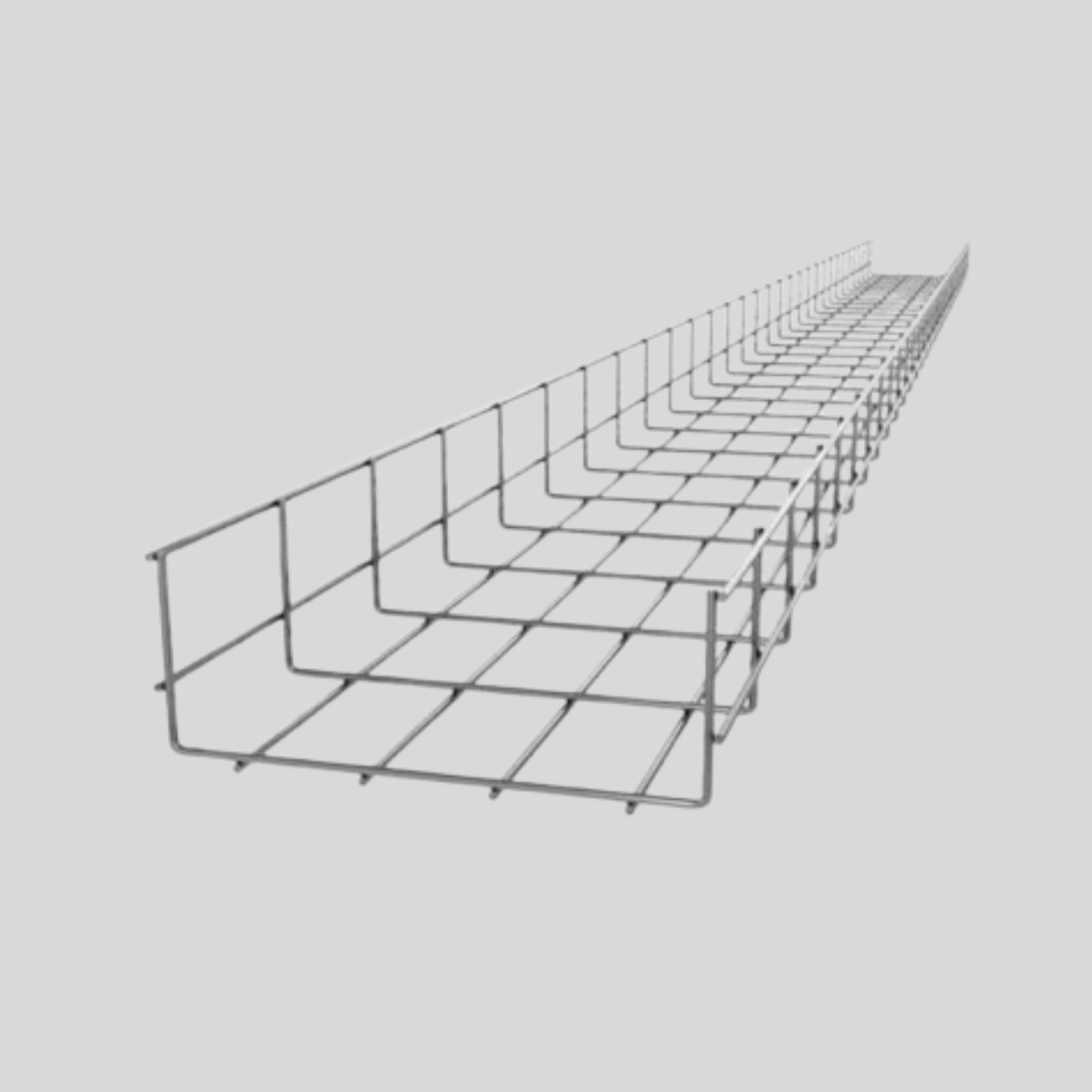

4. Mesh-Based Trays

For industries that value flexibility, mesh-based trays (also known as wire mesh trays or basket trays) are a great option. Made from steel wires arranged in a mesh form, these trays are lightweight, easy to cut, and customizable for on-site modifications.

Their open design not only provides natural ventilation but also simplifies cable installation and routing in complex layouts. Data centers and telecom sectors consistently use mesh trays due to their adaptability and cost-effectiveness.

5. Non-Conductive, Corrosion-Resistant Trays

In corrosive or chemical-heavy environments, metal trays may not last long. That’s where non-conductive,rust-proof trays play an important role. These trays are typically made of composite materials such as PVC or fiberglass, ensuring durability without compromising safety.

Since they are non-metallic, they eliminate the risk of electrical conductivity, making them suitable for highly sensitive electrical environments.

6. Fiberglass Cable Tray

A specialized type under the non-conductive category is the Fiberglass Cable Tray. Known for its high strength-to-weight ratio and resistance to moisture, chemicals, and extreme temperatures, fiberglass trays are widely used in marine, offshore, and chemical industries.

They provide long-term reliability and are maintenance-free compared to metallic trays, making them a cost-effective choice in harsh conditions.

7. Single-Rail Cable Tray

Unique in design, the Single-Rail Cable Tray uses a single central support system. This tray is often chosen for its sleek appearance and flexibility, especially in environments where aesthetics and quick installation are important.

Industries with tight spaces or architectural limitations benefit from single-rail trays because they allow cables to be installed and removed with ease.

8. Embossed Cable Tray

An Embossed Cable Tray is engineered to deliver extra strength and stability through its unique embossed design. The embossed pattern enhances the rigidity of the tray, minimizing bending or sagging even when carrying a heavy load of cables. This makes it a preferred choice for projects that demand both strength and long-term performance. Additionally, embossed trays provide improved grip for cables, reducing the chances of slippage or misalignment. They are suitable for industries that require secure, structured, and cost-effective cable management solutions. Their corrosion resistance and strong construction ensure reliable operation in harsh industrial environments.

9. Embossed Cable Tray High Strength Ladder Cable Tray(Without Welding)

The High Strength Ladder Cable Tray (Without Welding) is a modern solution that combines strength, durability, and ease of assembly. Unlike traditional trays, this design eliminates the need for welding, ensuring a cleaner finish and reducing the risk of weak joints. Its bolted or riveted structure delivers exceptional load-bearing capacity, making it suitable for heavy-duty industrial applications. This tray provides excellent ventilation for cables, ensuring safety and efficiency in electrical distribution systems. Its modular design also allows for easy customization and installation, saving both time and labor costs. It is an ideal choice for demanding cable management projects.

Choosing the Right Cable Tray for Your Industry

With multiple kinds/styles of cable trays available, the selection depends on specific requirements such as:

- Load capacity: Ladder trays for heavy-duty cable distribution, mesh trays for lightweight cabling.

- Environment: Non-conductive, corrosion-resistant trays or fiberglass cable trays for chemical plants and marine applications.

- Protection level: Solid base trays for contamination-free areas.

- Flexibility: Mesh-based trays and single-rail cable trays for quick installation and routing.

Cable trays are a key component of industrial setup, providing systematic, safe, and effective cabling systems. From the ladder-structured tray for power plants to corrosion-resistant fiberglass cable trays, every category has a specific function. Solid base trays, trough cable trays, or mesh-based trays – whatever your operational setup and cabling requirements are, there’s one perfect for you. By knowing the various types/styles of cable trays, industries can make rational choices, ensuring productivity,longer lifespan, and safety in electrical cable management.