Types of Cable Trays: A Complete Guide for Industrial Applications

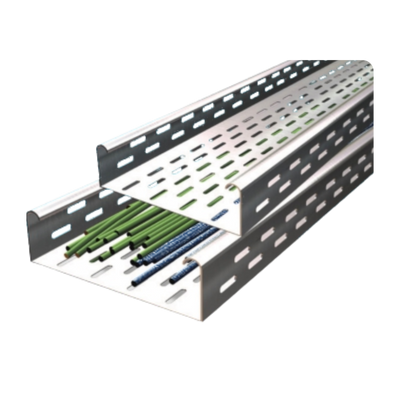

Types of Cable Trays: A Complete Guide for Industrial Applications In contemporary industries, effective cable management is not merely wire organization, it is about ensuring safety, longer life, and easy maintenance. That is where cable trays fit in. Cable trays are systems that are meant to support, guard, and route electrical cables in industrial settings like manufacturing plants, power stations, data centers, and business buildings. Depending on the application, load conditions, and ambient conditions, various types/styles of cable trays are available, so appropriate selection relies on them. Different Types of Cable Trays for Industrial Applications 1. Perforated Cable Tray When cables need more support than what ladder trays offer, industries turn to the Perforated Cable Tray. With closely spaced rungs or a bottom plate featuring small openings, this tray provides extra protection and partial ventilation. The trough design is ideal for moderate heat-generating cables, ensuring both support and airflow. Applications include commercial buildings, telecom industries, and IT setups where medium-sized cables are in use 2. Raceway (along with cover always) As the name suggests, Raceway (solid base trays) come with a completely covered bottom. This makes them the go-to choice when cables require maximum protection against dust, debris, and falling objects. Solid trays are common in food processing plants, paper mills, or cleanroom facilities where contamination is a serious concern. Since there is no ventilation, they are best suited for low-heat or sensitive cables. Industries that demand clean and shielded cabling benefit significantly from this design. 3. Ladder Cable Trays A Ladder Cable Tray is a widely used cable management system designed to support and route large volumes of power and communication cables. Its ladder-like structure allows for excellent ventilation, preventing overheating and ensuring longer cable life. The open design also makes it easy to install, inspect, and maintain cables without disrupting existing setups. Known for its durability and strength, ladder cable trays are ideal for industrial and commercial environments where heavy-duty cable support is required. They are commonly used in power plants, factories, and data centers to provide reliable, organized, and secure cable pathways. 4. Mesh-Based Trays For industries that value flexibility, mesh-based trays (also known as wire mesh trays or basket trays) are a great option. Made from steel wires arranged in a mesh form, these trays are lightweight, easy to cut, and customizable for on-site modifications. Their open design not only provides natural ventilation but also simplifies cable installation and routing in complex layouts. Data centers and telecom sectors consistently use mesh trays due to their adaptability and cost-effectiveness. 5. Non-Conductive, Corrosion-Resistant Trays In corrosive or chemical-heavy environments, metal trays may not last long. That’s where non-conductive,rust-proof trays play an important role. These trays are typically made of composite materials such as PVC or fiberglass, ensuring durability without compromising safety. Since they are non-metallic, they eliminate the risk of electrical conductivity, making them suitable for highly sensitive electrical environments. 6. Fiberglass Cable Tray A specialized type under the non-conductive category is the Fiberglass Cable Tray. Known for its high strength-to-weight ratio and resistance to moisture, chemicals, and extreme temperatures, fiberglass trays are widely used in marine, offshore, and chemical industries. They provide long-term reliability and are maintenance-free compared to metallic trays, making them a cost-effective choice in harsh conditions. 7. Single-Rail Cable Tray Unique in design, the Single-Rail Cable Tray uses a single central support system. This tray is often chosen for its sleek appearance and flexibility, especially in environments where aesthetics and quick installation are important. Industries with tight spaces or architectural limitations benefit from single-rail trays because they allow cables to be installed and removed with ease. 8. Embossed Cable Tray An Embossed Cable Tray is engineered to deliver extra strength and stability through its unique embossed design. The embossed pattern enhances the rigidity of the tray, minimizing bending or sagging even when carrying a heavy load of cables. This makes it a preferred choice for projects that demand both strength and long-term performance. Additionally, embossed trays provide improved grip for cables, reducing the chances of slippage or misalignment. They are suitable for industries that require secure, structured, and cost-effective cable management solutions. Their corrosion resistance and strong construction ensure reliable operation in harsh industrial environments. 9. Embossed Cable Tray High Strength Ladder Cable Tray(Without Welding) The High Strength Ladder Cable Tray (Without Welding) is a modern solution that combines strength, durability, and ease of assembly. Unlike traditional trays, this design eliminates the need for welding, ensuring a cleaner finish and reducing the risk of weak joints. Its bolted or riveted structure delivers exceptional load-bearing capacity, making it suitable for heavy-duty industrial applications. This tray provides excellent ventilation for cables, ensuring safety and efficiency in electrical distribution systems. Its modular design also allows for easy customization and installation, saving both time and labor costs. It is an ideal choice for demanding cable management projects. Choosing the Right Cable Tray for Your Industry With multiple kinds/styles of cable trays available, the selection depends on specific requirements such as: Load capacity: Ladder trays for heavy-duty cable distribution, mesh trays for lightweight cabling. Environment: Non-conductive, corrosion-resistant trays or fiberglass cable trays for chemical plants and marine applications. Protection level: Solid base trays for contamination-free areas. Flexibility: Mesh-based trays and single-rail cable trays for quick installation and routing. Cable trays are a key component of industrial setup, providing systematic, safe, and effective cabling systems. From the ladder-structured tray for power plants to corrosion-resistant fiberglass cable trays, every category has a specific function. Solid base trays, trough cable trays, or mesh-based trays – whatever your operational setup and cabling requirements are, there’s one perfect for you. By knowing the various types/styles of cable trays, industries can make rational choices, ensuring productivity,longer lifespan, and safety in electrical cable management.

Why Hot Dip Galvanizing is the Proven Standard for Corrosion Protection

Why Hot Dip Galvanizing is the Proven Standard for Corrosion Protection Steel has been the backbone of contemporary industry for many years, prized for its strength, versatility, and cost-effectiveness.Also, like any metal, steel is open to one significant vulnerability,corrosion. Untreated, it can destabilize frames, shorten lifespan, and create substantial maintenance expenses. That’s why hot dip galvanizing has come to be regarded as the most dependable way to shield steel. By submerging steel in molten zinc, the treatment forms a long-lasting barrier that protects the surface from water, chemicals, and atmospheric weathering. The Science Behind Zinc Coating Protection What is so good about galvanizing is the protection of the zinc coating. Throughout the process, the zinc metallurgically bonds to the steel and provides a coating that doesn’t merely stay on the surface but integrates into it. The bonding provides superb performance even when the surface is scratched or damaged because the zinc acts sacrificially and guards the underlying steel. In comparison to paints or sprays, it produces much more effective rust prevention coating. High-quality Galvanized Steel Strength Global industries trust on galvanizing due to the tested galvanized steel strength it provides. Whether in contact with rain, snow, or industrial chemicals, galvanized steel retains its durability and dependability. It has numerous applications in bridges, power structures, pipelines, and farm equipment, where durable steel protection is imperative. Unlike peelable and wear-off coatings, galvanized coats last decades with negligible maintenance. Looking for the Best Corrosion Protection? Discover how EFRA Industries LLP delivers trustworthy hot dip galvanizing solutions that ensure long-lasting steel protection, cost savings, and durability. Click here Providing Corrosion Resistance for Steel Corrosion is more than just a disturbance,it’s a costly issue that affects safety and function. Hot dip galvanizing offers high corrosion resistance for steel, protecting infrastructure, equipment, and buildings for longer. Galvanized steel is usually able to last 50–70 years. Depend on usage conditions and replacement needs, allowing industries to save money on repairs while delivering consistent performance. The Protective Value of a Zinc Layer One of the major benefits of hot dip galvanizing is the even protective layer of zinc that it forms. In contrast to paint, which will not cover corners or irregular surfaces, zinc runs over every corner and depression. This provides a thorough anti-corrosive surface finish that protects even the most inaccessible areas. Farmers, builders, and manufacturers can rest assured that their steel is protected all the way around, not only on exposed surfaces. Wide Industrial Galvanizing Applications A second reason galvanizing the high standard is its versatility. From building beams and guardrails to automotive components, irrigation systems, and solar installations, galvanized steel plays countless functions. These industrial applications of galvanizing showcase the versatility of the process across a variety of industries. Wherever durability, safety, and reliability are concerned, galvanized steel performs. A Cost-Effective Corrosion Solution Hot dip galvanizing can appear to be a more expensive upfront cost than conventional coatings, but it’s really a cost-efficient corrosion solution. With the long lifespan, lower re-application requirements, and less maintenance, it’s the economical option. For businesses, it translates into cost savings not just on the direct cost level but also in labor and downtime, making it the economic choice over the long term. Conclusion Hot dip galvanizing remains the most reliable technique used for steel protection. With its protective zinc coating, high galvanized steel durability, and superior corrosion resistance of steel, it keeps structures strong and reliable. Its protective zinc coating and extensive industrial applications of galvanizing offer many benefits, although it is an economical corrosion solution that provides long-lasting protection for steel. For industries that require reliability and sustainability, hot dip galvanizing is still the real gold standard. experience the lasting protection of hot dip galvanizing with EFRA Industries LLP, where reliability meets strength

Why Magnelis is the Smart Choice for Industrial Cable Tray Systems

Why Magnelis is the Smart Choice for Industrial Cable Tray Systems In contemporary industries, longer service lifespan and productivity are inseparable. Cable trays, which are the lifeline of electrical wire management, need to perform in hostile environments while ensuring safety and performance. For cable tray producers, the implementation of advanced automation has not only revolutionized production velocity and accuracy but also provided future-proof solutions. Amongst these, Magnelis coated cable trays are the future of rust-proof, sustainable, and environmentally friendly offerings. We leads the way with advanced Magnelis cable tray solutions, combining performance and advanced technology for tomorrow’s infrastructure The Role of Cable Trays in Modern Infrastructure From metros and smart cities to power plants of large units and IT hubs, industrial cable tray systems guarantee safety,productivity, and quality in electrical cabling.Typically, makers trust on hot dip galvanized cable trays for resistance to corrosion. Although effective, this practice is being replaced progressively by more advanced, eco-friendly solutions like Magnelis coated trays. How Automation is Transforming the Cable Tray Manufacturing Process The manufacturing process of cable trays has changed from hand cutting and bending to complete automation with robotics, CNC machinery, and AI quality checks. The major advantages of automation are: 1.Accurate engineering with less material wastage 2.24/7 production capacity for increased efficiency 3.Better quality with no human error 4.Customizable designs for unique cable tray systems 5.Improved safety with less human exposure to heat and chemicals Automation allows the manufacturers to experiment with new designs, provide complete consistency in quality and also help in increasing efficiency. Magnelis Coated Cable Trays – Cable Management’s Future In terms of performance over a longer period and sustainability, Magnelis coated cable trays are the outright winner. As opposed to conventional galvanization, Magnelis is a zinc-aluminum-magnesium alloy coating that provides: Exemplary Corrosion Resistance – Up to 3 times longer protection compared to conventional galvanization. Self-Healing Properties – Edges and scratches heal themselves against rust. Eco-Friendly Solution – Uses less coating material to lower environmental footprint and promote sustainable cable tray manufacturing. Cost-Effectiveness – Longer life cuts replacement and maintenance costs. Versatility – Best choice for offshore settings, chemical facilities, and outside installation where toughness is highly important. This technology is leading the way towards more sustainable cable trays that keep pace with international sustainability aspirations without sacrificing strength or stability. Hot Dip Galvanization vs. Magnelis While hot dip galvanized cable trays have served industries for many years, they require more zinc, energy, and resources, making them less sustainable. Moreover, their protective layer can wear out faster in aggressive environments. In contrast, Magnelis coated trays provide: Longer-lasting protection and self expanssion of Zinc coating in harsh climates Reduced environmental footprint Compatibility with automated production processes Stronger appeal for industries aiming for green certifications It’s clear that the future of advanced cable tray designs lies with Magnelis technology. Sustainability Through Automation and Magnelis Today’s manufacturers face the challenge of meeting demand while being environmentally responsible. Combining automation with Magnelis offers the perfect solution: Optimized material usage through automated cutting and punching Lower Power consumption in production Recyclable materials supporting circular economy models Eco-friendly coatings that last longer and reduce replacements These advances make sustainable cable tray production not just a trend but a Cable Tray as per standard IEC 61537. Uses of Magnelis Coated Cable Trays Due to their unmatched strength and longevity, Magnelis trays are the go-to choice in industries: Power Plants & Utilities – High protection in moist zones Oil & Gas Facilities – Withstand corrosive offshore conditions Smart Cities & Infrastructure Projects – Accommodating green cable trays in big-unit schemes Data Centers – Providing neat, corrosion-proof systems for mission-critical IT configurations Looking for a trusted cable tray manufacturer who delivers the future of Magnelis technology? Partner with EFRA Industries LLP now! Get a Quote Why Choose a Magnelis-Focused Cable Tray Manufacturer? Not all manufacturers are future-ready. When choosing a partner, ensure they are experts in automated cable tray manufacturing with Magnelis technology. This ensures: High-quality corrosion resistant cable trays Eco-friendly and sustainable solutions Long-term cost savings through reduced maintenance Innovative designs customized for industrial needs The future of the cable tray manufacturing process is marked by innovation and automation. The role that hot dip galvanizing used to play, though, it is Magnelis coated cable trays that are defining the future, providing unmatched longevity,Environmental responsibility, and eco-friendliness.For companies looking for trustable industrial cable tray systems, the decision is obvious, partner with a leading cable tray manufacturer that adopts automated Magnelis production. The outcome is not only stronger infrastructure but a smarter, cleaner, and more sustainable future.

Introducing EFRA: Your Trusted Partner for Innovative Solutions

EFRA has emerged as a dynamic leader in delivering cutting-edge solutions tailored to meet the evolving needs of modern businesses. With a commitment to excellence and customer-centricity, EFRA specializes in [insert services/products], ensuring clients achieve their goals efficiently. Their team of experts combines innovation with industry knowledge to provide results that matter.Why Choose EFRA? Their dedication to quality, timely delivery, and bespoke solutions make them the partner of choice for businesses across sectors.

How EFRA’s Expertise Drives Business Success

In today’s competitive landscape, having a reliable partner like EFRA can make all the difference. EFRA offers a range of high-quality designed to optimize your operations. From [example offering 1] to [example offering 2], their solutions cater to diverse industries with precision and care.With years of experience and a robust infrastructure, EFRA guarantees the perfect blend of innovation and reliability.

EFRA’s Commitment to Quality: Building Long-Term Partnerships

At EFRA, quality isn’t just a goal—it’s a promise. Every project undertaken reflects their unwavering focus on delivering superior value to clients. Their processes adhere to the highest standards, ensuring every product and service aligns with customer expectations.By fostering trust and transparency, EFRA has built a reputation for excellence that continues to grow with each partnership.